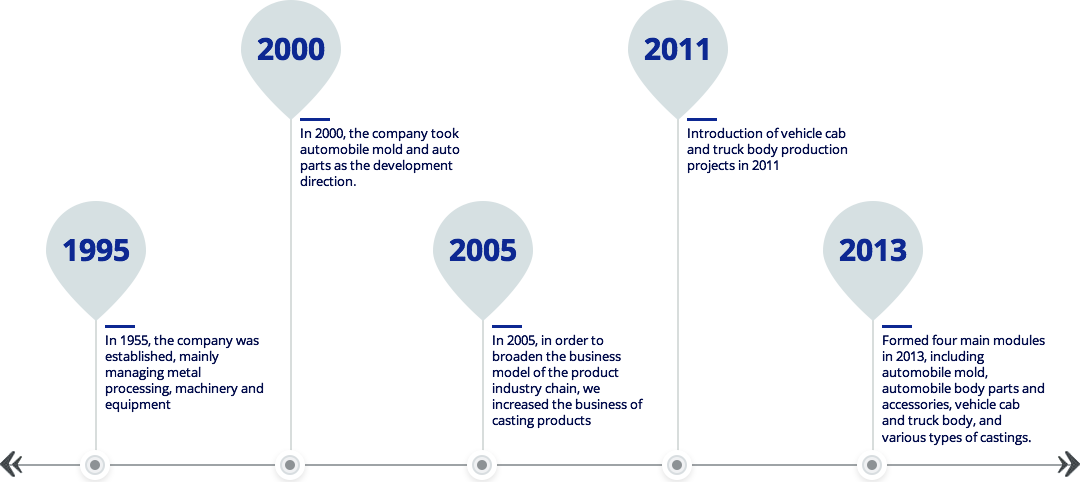

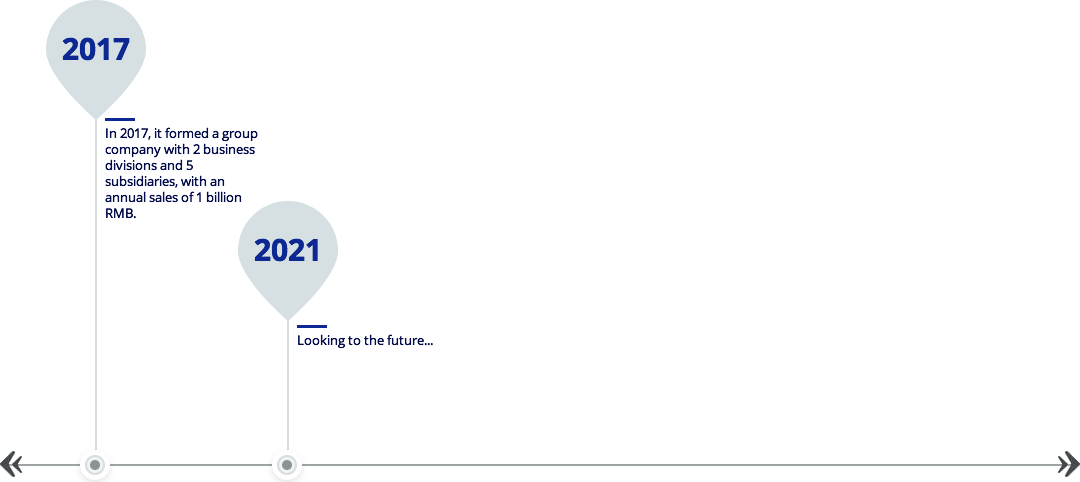

Qingdao Hailong Machinery Group Co., Ltd.

is one of leading machinery manufacturer in China. Total assets is more $200 million;

Hailong is a national high-tech enterprise, Obtained IATF16949, ISO14001, ISO9001 and OHSAS18001.

We offer complete solution for automotive industrial, Including auto molds, inspection tools, automobile stamping parts, truck cabs, truck bodies and special modified vehicles. The products are exported to the United States, UK, Germany, Africa , etc.

Hailong Group have 5 branch companies:

1. Qingdao Jitai Auto Mould Co., Ltd.,

2. Yantai Haijie Auto Parts Co., Ltd.,

3. Qingdao Haishun Jihua Machinery Co., Ltd.,

4. Qingdao Longtai Runda Auto Parts Co., Ltd.,

5. Qingdao Taihengda Precision Mould Co., Ltd.

Hailong is the member of China Die & Mould Industry Association, a director of Shandong Foundry Association.

We has successively won the "Top 100 Enterprises" in the Machinery Industry of Shandong Province,

"Key Mould Enterprises in China",

Qingdao Top 100 Private Technology Enterprises,

"specialized, refined, and new" enterprises.

Over the years, Hailong has followed the business philosophy of "quality first, customer first; abide by credit and sincere service", and has established a good reputation by virtue of excellent product quality and wonderful service.

Get long-term and stable cooperation with FAW, SAIC GM, BAIC New Energy, FAW Mould companies.

The auto parts division is mainly engaged in the auto parts stamping and welding, and making L-plates for auto longitudinal beams.

With advance stamping lines: 8250T automatic stamping line; 3400T automatic stamping line; J39-800T-2400T stamping line; J36-630T-800T stamping lines; J31-400T-2000T single-point thick plate stamping line; J23- Two 63T-200T small punching lines; vertical spot welding machine, suspension welding machine, laser cutting machine, CNC plate punching machine, shearing machine, bending machine and other equipment, which can produce stretching, drawing, pressing and punching, etc. The stamping products of each process are also capable of producing post-processing processes such as plasma cutting, welding and trimming.

8250T automatic stamping line have reached the international advanced level of similar products. The instantaneous beat of the entire line of equipment is 12 times/min, and the average effective beat can reach 9 times/min, which greatly improves production efficiency, effectively guarantees product quality, and can produce various types Outer cover parts for automobile.

Our stamping and welding equipment has complete models and large tonnage spans. It can produce and process different types and specifications of automobile panels and skeleton parts. It has rapid switching and processing capabilities from small batches to mass production, high operating efficiency and fast delivery with stable quality.

The Special Vehicle Division mainly produce complete commercial vehicle cabs and truck bodies. We have several professional production lines for complete vehicle cabs and truck bodies. Including rolling, welding, painting, etc., 1 light truck cab welding line, 1 heavy truck cab welding line, and 13 light truck bodies rolling lines, 2 truck bodies welding lines and 1 high-standard electrophoretic coating line. Well meet different types of vehicle cabs and truck bodies production. The light truck cab welding production line is equipped with four sets of welding robots, and the overall reciprocating rod conveying can produce different series of light truck cab products such as 1735, 1835, 1985, etc.; the heavy truck cab welding line can produce JH6+ living cabin series cab products.

Jitai company was founded in 1993, mainly specialized in producing metal stamping die for vehicle body cover system as well as various of sheet metal fabrication parts.Jitai is National High Technology Corporation, China mold industry association group member. Jitai has got through ISO9001 international quality management system, ISO14001 environment management system and ISO45001 career health management system certification.

After 20 years’ development, Jitai owns rich and strong technical research ability, stamping die making and production manangement experience, has a batch of hardware and software facilities. Has completely business developing ability from die design, die making to die machining, testing ,assembling, debugging . can effectively strengthen the work plan ensure the product quality and delivery time.

Jitai company is quality-oriented, committed to providing professional and integrated services for automobile OEMs and stamping factories.Relying on high quality product and service,We have established long term and stable cooperation relations with domestic and foreigh companies.

Qingdao Haishun Jihua Machinery Co., Ltd. was funded in 2004 , mainly produce vehicle mold casting, and machine tool casting products, is member of Shandong casting foundry association.Haishunjihua has got through ISO9001 international quality management system , ISO14001 environment management system and OHSAS18001 career health management system certification.

Haishunjihua Company adopts resin sand and expendeable pattern production technology which can produce various model of grey iron and ductile iron casting products.Single casting weight can be up to 20 Ton.Haishunjihua company owns advanced equipment ,including resin sand production line, medium frequency smelting furnace, large scale shot blasting room and matched with a completely set of advanced testing equips, such as spectrum analyzer, metallographic microscope ,universal material tester to inspect the mechanical and physical feature of the casting products.

The company main customer includes :FAW mold, BAIC, GAC Honda, South Korea Doosan, Yantai Doosan, the United States GD Company, South Korea Huachuan Company, etc The annual production capacity is 12,000-15,000 tons, and the annual output value is 100-120 million yuan.

Haishunjihua will obey developing idea of “insist on independent new creation, delvelop circle economy, build green factory”,committed to development and application of industry top leading technology, perfecting process technology, constantly optimizing product structure, creating greater value for customers, and striving to build an evergreen enterprise with competitiveness and innovation ability.

Haijie company was founded in 2011, mainly produces automotive stamping parts for Dongyue Base of Shanghai GM. The company is a strategic partner of SAIC-GM.It has got through the IATF16949 quality management system certification, and won the title of "Annual Excellent Second Level Supplier" in the supplier evaluation of GM for many times.

The company has three production lines of flow stamping, equipped with industrial robots, which can continuously finish six series of cold pressing flow operations, such as stretching, punching, bending, trimming, forming and automatic waste collection, transportation and loading. The annual punching capacity reaches 30 million times, and the company can produce all kinds of internal and external plate coverings and sheet parts of passenger cars.

Since the establishment, the company has always been to "meet and exceed customer demand" for the purpose, based on the "safe production", the pursuit of quality management system and effective integration of enterprise production and management, take the daily briefing, QSB quick meeting, weekly meeting every week, monthly safety meeting, the scene "5 s" management, visual management and a series of measures to improve the level of company management, efforts to bring the company into a first-class, with modern advanced management mode of auto parts manufacturing enterprises

Taihengda is mainly majored in the designing , machining, manufacturing of vehicle metal fabrication steel die, metal stamping parts & die, vehicle parts, inserted die for large mould.

Taihengda has over 30 sets of various of machining equipments, including CNC gantry milling machine, cnc machining center, cnc drilling machine, large grinding machine,lathe machine, milling machine, drilling machine, wire cutting machine and metal stamping machine etc.

Since its establishment, the company has always believed in the principle of "customer first, quality first", followed the business policy of "customer service, customer convenience", quality-oriented, with good faith management, is committed to providing customers with the best products and services.

We will contact you with in 24 hours.